Unlocking the Flow: UL FM Gate Valves for Wholesale Buyers – Your Ultimate Guide to Reliable Fire Protection Solutions

2025-12-22

Looking for a reliable fire protection solution that doesn't compromise on safety or efficiency? You've come to the right place. In the world of wholesale procurement, UL FM gate valves stand out as a critical component, ensuring seamless operation and robust protection in emergency scenarios. With so many options available, it's essential to choose a partner you can trust. That's where DRIFCO steps in, offering top-tier wholesale solutions that are as dependable as they are innovative. This guide will delve into everything you need to know about these vital valves, from their advanced features to practical buying tips. Get ready to explore how DRIFCO's expertise can unlock superior fire safety for your business—let's dive in and elevate your fire protection strategy today.

What Are UL FM Gate Valves and Why They Matter for Fire Safety

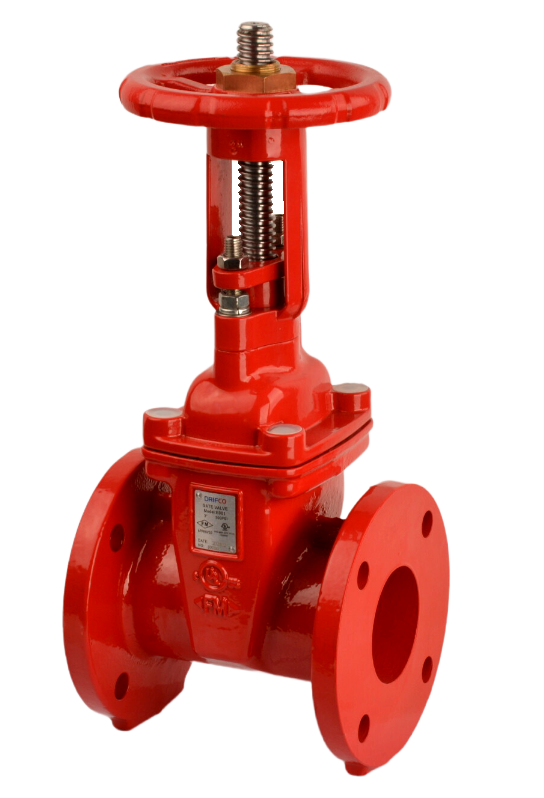

UL FM gate valves are specialized components designed specifically for fire protection systems, rigorously tested and certified by Underwriters Laboratories (UL) and Factory Mutual (FM). Unlike standard industrial valves, these devices are built to withstand extreme conditions—think blazing heat, high pressure, and sudden impacts—without compromising their ability to control water flow. Picture a valve that can endure a fire for hours yet still shut off smoothly when needed; that's the kind of robustness UL FM certification demands.

Why does this matter so much for fire safety? When a fire erupts, every second counts, and a valve failure could mean the difference between containment and catastrophe. UL FM gate valves provide reliability that general-purpose valves simply can't match—they're the unsung heroes that ensure sprinkler systems activate correctly and fire hydrants deliver water without hiccups. It's not just about meeting codes; it's about preventing a minor malfunction from escalating into a life-threatening emergency.

Beyond mere compliance, choosing UL FM certified valves reflects a proactive safety mindset. In industries like manufacturing, warehousing, or healthcare, where fire risks are elevated, these valves offer peace of mind that's backed by decades of testing. They stand out from generic alternatives by blending durability with precision, making them a smart investment for anyone serious about safeguarding people and property. So, next time you see a fire safety inspection, remember that a tiny valve might be playing one of the biggest roles in keeping everyone safe.

Key Features to Look for When Buying Wholesale Gate Valves

UL FM gate valves are specialized components designed specifically for fire protection systems, rigorously tested and certified by Underwriters Laboratories (UL) and Factory Mutual (FM). Unlike standard industrial valves, these devices are built to withstand extreme conditions—think blazing heat, high pressure, and sudden impacts—without compromising their ability to control water flow. Picture a valve that can endure a fire for hours yet still shut off smoothly when needed; that's the kind of robustness UL FM certification demands.

Why does this matter so much for fire safety? When a fire erupts, every second counts, and a valve failure could mean the difference between containment and catastrophe. UL FM gate valves provide reliability that general-purpose valves simply can't match—they're the unsung heroes that ensure sprinkler systems activate correctly and fire hydrants deliver water without hiccups. It's not just about meeting codes; it's about preventing a minor malfunction from escalating into a life-threatening emergency.

Beyond mere compliance, choosing UL FM certified valves reflects a proactive safety mindset. In industries like manufacturing, warehousing, or healthcare, where fire risks are elevated, these valves offer peace of mind that's backed by decades of testing. They stand out from generic alternatives by blending durability with precision, making them a smart investment for anyone serious about safeguarding people and property. So, next time you see a fire safety inspection, remember that a tiny valve might be playing one of the biggest roles in keeping everyone safe.

When sourcing wholesale gate valves, it's essential to focus on core aspects like material composition and pressure ratings. For instance, opting for stainless steel or ductile iron can significantly enhance durability in corrosive environments, while checking ANSI pressure classes ensures the valves can handle your specific system demands without premature failure. This groundwork helps avoid costly replacements down the line.

Beyond the basics, don't overlook design features such as stem type and sealing mechanisms. Rising stem valves offer clear visual indicators of open or closed positions, which is handy for maintenance, and resilient seats can provide tighter seals in high-pressure applications. Considering these nuances ensures you get valves that not only meet specs but also integrate seamlessly into your operational workflow.

Lastly, factor in testing certifications and manufacturer reputation. Look for valves that come with documented API or ISO test results to verify performance under stress. Partnering with trusted suppliers known for consistent quality can streamline procurement and reduce risks, making your wholesale investment more reliable and efficient in the long run.

How UL FM Gate Valves Enhance Fire Protection System Reliability

UL FM gate valves are specialized components designed specifically for fire protection systems, rigorously tested and certified by Underwriters Laboratories (UL) and Factory Mutual (FM). Unlike standard industrial valves, these devices are built to withstand extreme conditions—think blazing heat, high pressure, and sudden impacts—without compromising their ability to control water flow. Picture a valve that can endure a fire for hours yet still shut off smoothly when needed; that's the kind of robustness UL FM certification demands.

Why does this matter so much for fire safety? When a fire erupts, every second counts, and a valve failure could mean the difference between containment and catastrophe. UL FM gate valves provide reliability that general-purpose valves simply can't match—they're the unsung heroes that ensure sprinkler systems activate correctly and fire hydrants deliver water without hiccups. It's not just about meeting codes; it's about preventing a minor malfunction from escalating into a life-threatening emergency.

Beyond mere compliance, choosing UL FM certified valves reflects a proactive safety mindset. In industries like manufacturing, warehousing, or healthcare, where fire risks are elevated, these valves offer peace of mind that's backed by decades of testing. They stand out from generic alternatives by blending durability with precision, making them a smart investment for anyone serious about safeguarding people and property. So, next time you see a fire safety inspection, remember that a tiny valve might be playing one of the biggest roles in keeping everyone safe.

When sourcing wholesale gate valves, it's essential to focus on core aspects like material composition and pressure ratings. For instance, opting for stainless steel or ductile iron can significantly enhance durability in corrosive environments, while checking ANSI pressure classes ensures the valves can handle your specific system demands without premature failure. This groundwork helps avoid costly replacements down the line.

Beyond the basics, don't overlook design features such as stem type and sealing mechanisms. Rising stem valves offer clear visual indicators of open or closed positions, which is handy for maintenance, and resilient seats can provide tighter seals in high-pressure applications. Considering these nuances ensures you get valves that not only meet specs but also integrate seamlessly into your operational workflow.

Lastly, factor in testing certifications and manufacturer reputation. Look for valves that come with documented API or ISO test results to verify performance under stress. Partnering with trusted suppliers known for consistent quality can streamline procurement and reduce risks, making your wholesale investment more reliable and efficient in the long run.

UL FM gate valves play a pivotal role in boosting the reliability of fire protection systems by adhering to stringent certification standards that ensure robust performance under extreme conditions. These valves undergo rigorous testing for factors like pressure endurance, corrosion resistance, and operational consistency, which helps prevent failures during critical fire events. By integrating UL FM certified gate valves, systems gain an extra layer of trust, as they are designed to maintain integrity and functionality even in harsh environments, ultimately reducing the risk of system malfunctions when every second counts.

One key way these valves enhance reliability is through their precise engineering, which includes features like durable materials and leak-proof sealing mechanisms. Unlike standard valves, UL FM gate valves are specifically tailored to meet the demands of fire protection, offering superior flow control and minimal pressure drop. This ensures that water or other extinguishing agents are delivered efficiently and without interruption, which is crucial for containing fires quickly and effectively, thereby improving overall system response times and safety.

Additionally, the use of UL FM gate valves contributes to system longevity and lower maintenance needs, further bolstering reliability. Their certification process mandates regular inspections and quality checks, which translate into fewer unexpected breakdowns and extended service life. This proactive approach not only safeguards against potential system failures but also supports compliance with industry regulations, making UL FM gate valves a smart investment for any fire protection strategy aiming for peak reliability and peace of mind.

Practical Applications and Industries Using These Valves

UL FM gate valves are specialized components designed specifically for fire protection systems, rigorously tested and certified by Underwriters Laboratories (UL) and Factory Mutual (FM). Unlike standard industrial valves, these devices are built to withstand extreme conditions—think blazing heat, high pressure, and sudden impacts—without compromising their ability to control water flow. Picture a valve that can endure a fire for hours yet still shut off smoothly when needed; that's the kind of robustness UL FM certification demands.

Why does this matter so much for fire safety? When a fire erupts, every second counts, and a valve failure could mean the difference between containment and catastrophe. UL FM gate valves provide reliability that general-purpose valves simply can't match—they're the unsung heroes that ensure sprinkler systems activate correctly and fire hydrants deliver water without hiccups. It's not just about meeting codes; it's about preventing a minor malfunction from escalating into a life-threatening emergency.

Beyond mere compliance, choosing UL FM certified valves reflects a proactive safety mindset. In industries like manufacturing, warehousing, or healthcare, where fire risks are elevated, these valves offer peace of mind that's backed by decades of testing. They stand out from generic alternatives by blending durability with precision, making them a smart investment for anyone serious about safeguarding people and property. So, next time you see a fire safety inspection, remember that a tiny valve might be playing one of the biggest roles in keeping everyone safe.

When sourcing wholesale gate valves, it's essential to focus on core aspects like material composition and pressure ratings. For instance, opting for stainless steel or ductile iron can significantly enhance durability in corrosive environments, while checking ANSI pressure classes ensures the valves can handle your specific system demands without premature failure. This groundwork helps avoid costly replacements down the line.

Beyond the basics, don't overlook design features such as stem type and sealing mechanisms. Rising stem valves offer clear visual indicators of open or closed positions, which is handy for maintenance, and resilient seats can provide tighter seals in high-pressure applications. Considering these nuances ensures you get valves that not only meet specs but also integrate seamlessly into your operational workflow.

Lastly, factor in testing certifications and manufacturer reputation. Look for valves that come with documented API or ISO test results to verify performance under stress. Partnering with trusted suppliers known for consistent quality can streamline procurement and reduce risks, making your wholesale investment more reliable and efficient in the long run.

UL FM gate valves play a pivotal role in boosting the reliability of fire protection systems by adhering to stringent certification standards that ensure robust performance under extreme conditions. These valves undergo rigorous testing for factors like pressure endurance, corrosion resistance, and operational consistency, which helps prevent failures during critical fire events. By integrating UL FM certified gate valves, systems gain an extra layer of trust, as they are designed to maintain integrity and functionality even in harsh environments, ultimately reducing the risk of system malfunctions when every second counts.

One key way these valves enhance reliability is through their precise engineering, which includes features like durable materials and leak-proof sealing mechanisms. Unlike standard valves, UL FM gate valves are specifically tailored to meet the demands of fire protection, offering superior flow control and minimal pressure drop. This ensures that water or other extinguishing agents are delivered efficiently and without interruption, which is crucial for containing fires quickly and effectively, thereby improving overall system response times and safety.

Additionally, the use of UL FM gate valves contributes to system longevity and lower maintenance needs, further bolstering reliability. Their certification process mandates regular inspections and quality checks, which translate into fewer unexpected breakdowns and extended service life. This proactive approach not only safeguards against potential system failures but also supports compliance with industry regulations, making UL FM gate valves a smart investment for any fire protection strategy aiming for peak reliability and peace of mind.

In industries like oil and gas, these valves are essential for controlling the flow of hazardous materials, ensuring safety in high-pressure pipelines and refining processes. Their robust design withstands extreme conditions, preventing leaks and operational mishaps, which is crucial for maintaining environmental compliance and worker safety.

Water treatment facilities rely on these valves to manage purification cycles and distribution systems, enabling precise adjustments for different water qualities and volumes. This adaptability helps municipalities optimize resource use and meet stringent regulatory standards, improving overall efficiency in public utility operations.

Manufacturing sectors, including automotive and aerospace, utilize these valves for automated production lines, where they regulate cooling systems, hydraulic presses, and assembly processes. Their integration with smart technologies allows for real-time monitoring and adjustments, reducing downtime and enhancing productivity in competitive markets.

Cost-Effective Sourcing Strategies for Wholesale Buyers

UL FM gate valves are specialized components designed specifically for fire protection systems, rigorously tested and certified by Underwriters Laboratories (UL) and Factory Mutual (FM). Unlike standard industrial valves, these devices are built to withstand extreme conditions—think blazing heat, high pressure, and sudden impacts—without compromising their ability to control water flow. Picture a valve that can endure a fire for hours yet still shut off smoothly when needed; that's the kind of robustness UL FM certification demands.

Why does this matter so much for fire safety? When a fire erupts, every second counts, and a valve failure could mean the difference between containment and catastrophe. UL FM gate valves provide reliability that general-purpose valves simply can't match—they're the unsung heroes that ensure sprinkler systems activate correctly and fire hydrants deliver water without hiccups. It's not just about meeting codes; it's about preventing a minor malfunction from escalating into a life-threatening emergency.

Beyond mere compliance, choosing UL FM certified valves reflects a proactive safety mindset. In industries like manufacturing, warehousing, or healthcare, where fire risks are elevated, these valves offer peace of mind that's backed by decades of testing. They stand out from generic alternatives by blending durability with precision, making them a smart investment for anyone serious about safeguarding people and property. So, next time you see a fire safety inspection, remember that a tiny valve might be playing one of the biggest roles in keeping everyone safe.

When sourcing wholesale gate valves, it's essential to focus on core aspects like material composition and pressure ratings. For instance, opting for stainless steel or ductile iron can significantly enhance durability in corrosive environments, while checking ANSI pressure classes ensures the valves can handle your specific system demands without premature failure. This groundwork helps avoid costly replacements down the line.

Beyond the basics, don't overlook design features such as stem type and sealing mechanisms. Rising stem valves offer clear visual indicators of open or closed positions, which is handy for maintenance, and resilient seats can provide tighter seals in high-pressure applications. Considering these nuances ensures you get valves that not only meet specs but also integrate seamlessly into your operational workflow.

Lastly, factor in testing certifications and manufacturer reputation. Look for valves that come with documented API or ISO test results to verify performance under stress. Partnering with trusted suppliers known for consistent quality can streamline procurement and reduce risks, making your wholesale investment more reliable and efficient in the long run.

UL FM gate valves play a pivotal role in boosting the reliability of fire protection systems by adhering to stringent certification standards that ensure robust performance under extreme conditions. These valves undergo rigorous testing for factors like pressure endurance, corrosion resistance, and operational consistency, which helps prevent failures during critical fire events. By integrating UL FM certified gate valves, systems gain an extra layer of trust, as they are designed to maintain integrity and functionality even in harsh environments, ultimately reducing the risk of system malfunctions when every second counts.

One key way these valves enhance reliability is through their precise engineering, which includes features like durable materials and leak-proof sealing mechanisms. Unlike standard valves, UL FM gate valves are specifically tailored to meet the demands of fire protection, offering superior flow control and minimal pressure drop. This ensures that water or other extinguishing agents are delivered efficiently and without interruption, which is crucial for containing fires quickly and effectively, thereby improving overall system response times and safety.

Additionally, the use of UL FM gate valves contributes to system longevity and lower maintenance needs, further bolstering reliability. Their certification process mandates regular inspections and quality checks, which translate into fewer unexpected breakdowns and extended service life. This proactive approach not only safeguards against potential system failures but also supports compliance with industry regulations, making UL FM gate valves a smart investment for any fire protection strategy aiming for peak reliability and peace of mind.

In industries like oil and gas, these valves are essential for controlling the flow of hazardous materials, ensuring safety in high-pressure pipelines and refining processes. Their robust design withstands extreme conditions, preventing leaks and operational mishaps, which is crucial for maintaining environmental compliance and worker safety.

Water treatment facilities rely on these valves to manage purification cycles and distribution systems, enabling precise adjustments for different water qualities and volumes. This adaptability helps municipalities optimize resource use and meet stringent regulatory standards, improving overall efficiency in public utility operations.

Manufacturing sectors, including automotive and aerospace, utilize these valves for automated production lines, where they regulate cooling systems, hydraulic presses, and assembly processes. Their integration with smart technologies allows for real-time monitoring and adjustments, reducing downtime and enhancing productivity in competitive markets.

For wholesale buyers navigating today's competitive markets, cost-effective sourcing isn't just about finding the cheapest suppliers; it's about identifying opportunities that maximize value while minimizing unnecessary expenses. A smart approach involves leveraging global supply chains to tap into lower-cost regions, such as Southeast Asia or Eastern Europe, where production costs may be lower without sacrificing quality. By diversifying your sourcing portfolio, you can mitigate risks like currency fluctuations or geopolitical tensions that might disrupt single-source dependencies. This strategy not only reduces costs but also enhances resilience, ensuring a steady flow of inventory to meet consumer demand.

Another key aspect is building strong, long-term relationships with suppliers rather than constantly switching for marginal savings. Negotiating bulk purchase agreements and flexible payment terms can lead to significant discounts and better pricing over time. Additionally, consider incorporating sustainable and ethical sourcing practices, as many consumers now favor brands that prioritize social responsibility. This can open doors to premium market segments and reduce risks associated with supply chain scandals, ultimately contributing to a more cost-efficient and reputable business model.

Technology also plays a crucial role in streamlining sourcing processes. Utilizing digital tools like e-procurement platforms and data analytics can help buyers identify cost-saving opportunities, such as spotting trends in material costs or optimizing logistics routes. By automating routine tasks and enhancing transparency, businesses can cut down on administrative overhead and make more informed decisions. Embracing innovation in this way doesn't just lower immediate expenses—it positions you to adapt quickly to market changes, staying ahead of competitors who rely on outdated methods.

Maintenance Tips to Ensure Long-Term Valve Performance

UL FM gate valves are specialized components designed specifically for fire protection systems, rigorously tested and certified by Underwriters Laboratories (UL) and Factory Mutual (FM). Unlike standard industrial valves, these devices are built to withstand extreme conditions—think blazing heat, high pressure, and sudden impacts—without compromising their ability to control water flow. Picture a valve that can endure a fire for hours yet still shut off smoothly when needed; that's the kind of robustness UL FM certification demands.

Why does this matter so much for fire safety? When a fire erupts, every second counts, and a valve failure could mean the difference between containment and catastrophe. UL FM gate valves provide reliability that general-purpose valves simply can't match—they're the unsung heroes that ensure sprinkler systems activate correctly and fire hydrants deliver water without hiccups. It's not just about meeting codes; it's about preventing a minor malfunction from escalating into a life-threatening emergency.

Beyond mere compliance, choosing UL FM certified valves reflects a proactive safety mindset. In industries like manufacturing, warehousing, or healthcare, where fire risks are elevated, these valves offer peace of mind that's backed by decades of testing. They stand out from generic alternatives by blending durability with precision, making them a smart investment for anyone serious about safeguarding people and property. So, next time you see a fire safety inspection, remember that a tiny valve might be playing one of the biggest roles in keeping everyone safe.

When sourcing wholesale gate valves, it's essential to focus on core aspects like material composition and pressure ratings. For instance, opting for stainless steel or ductile iron can significantly enhance durability in corrosive environments, while checking ANSI pressure classes ensures the valves can handle your specific system demands without premature failure. This groundwork helps avoid costly replacements down the line.

Beyond the basics, don't overlook design features such as stem type and sealing mechanisms. Rising stem valves offer clear visual indicators of open or closed positions, which is handy for maintenance, and resilient seats can provide tighter seals in high-pressure applications. Considering these nuances ensures you get valves that not only meet specs but also integrate seamlessly into your operational workflow.

Lastly, factor in testing certifications and manufacturer reputation. Look for valves that come with documented API or ISO test results to verify performance under stress. Partnering with trusted suppliers known for consistent quality can streamline procurement and reduce risks, making your wholesale investment more reliable and efficient in the long run.

UL FM gate valves play a pivotal role in boosting the reliability of fire protection systems by adhering to stringent certification standards that ensure robust performance under extreme conditions. These valves undergo rigorous testing for factors like pressure endurance, corrosion resistance, and operational consistency, which helps prevent failures during critical fire events. By integrating UL FM certified gate valves, systems gain an extra layer of trust, as they are designed to maintain integrity and functionality even in harsh environments, ultimately reducing the risk of system malfunctions when every second counts.

One key way these valves enhance reliability is through their precise engineering, which includes features like durable materials and leak-proof sealing mechanisms. Unlike standard valves, UL FM gate valves are specifically tailored to meet the demands of fire protection, offering superior flow control and minimal pressure drop. This ensures that water or other extinguishing agents are delivered efficiently and without interruption, which is crucial for containing fires quickly and effectively, thereby improving overall system response times and safety.

Additionally, the use of UL FM gate valves contributes to system longevity and lower maintenance needs, further bolstering reliability. Their certification process mandates regular inspections and quality checks, which translate into fewer unexpected breakdowns and extended service life. This proactive approach not only safeguards against potential system failures but also supports compliance with industry regulations, making UL FM gate valves a smart investment for any fire protection strategy aiming for peak reliability and peace of mind.

In industries like oil and gas, these valves are essential for controlling the flow of hazardous materials, ensuring safety in high-pressure pipelines and refining processes. Their robust design withstands extreme conditions, preventing leaks and operational mishaps, which is crucial for maintaining environmental compliance and worker safety.

Water treatment facilities rely on these valves to manage purification cycles and distribution systems, enabling precise adjustments for different water qualities and volumes. This adaptability helps municipalities optimize resource use and meet stringent regulatory standards, improving overall efficiency in public utility operations.

Manufacturing sectors, including automotive and aerospace, utilize these valves for automated production lines, where they regulate cooling systems, hydraulic presses, and assembly processes. Their integration with smart technologies allows for real-time monitoring and adjustments, reducing downtime and enhancing productivity in competitive markets.

For wholesale buyers navigating today's competitive markets, cost-effective sourcing isn't just about finding the cheapest suppliers; it's about identifying opportunities that maximize value while minimizing unnecessary expenses. A smart approach involves leveraging global supply chains to tap into lower-cost regions, such as Southeast Asia or Eastern Europe, where production costs may be lower without sacrificing quality. By diversifying your sourcing portfolio, you can mitigate risks like currency fluctuations or geopolitical tensions that might disrupt single-source dependencies. This strategy not only reduces costs but also enhances resilience, ensuring a steady flow of inventory to meet consumer demand.

Another key aspect is building strong, long-term relationships with suppliers rather than constantly switching for marginal savings. Negotiating bulk purchase agreements and flexible payment terms can lead to significant discounts and better pricing over time. Additionally, consider incorporating sustainable and ethical sourcing practices, as many consumers now favor brands that prioritize social responsibility. This can open doors to premium market segments and reduce risks associated with supply chain scandals, ultimately contributing to a more cost-efficient and reputable business model.

Technology also plays a crucial role in streamlining sourcing processes. Utilizing digital tools like e-procurement platforms and data analytics can help buyers identify cost-saving opportunities, such as spotting trends in material costs or optimizing logistics routes. By automating routine tasks and enhancing transparency, businesses can cut down on administrative overhead and make more informed decisions. Embracing innovation in this way doesn't just lower immediate expenses—it positions you to adapt quickly to market changes, staying ahead of competitors who rely on outdated methods.

Keeping valves in top shape isn't just about preventing breakdowns; it's about ensuring they operate smoothly and efficiently over years of service. Regular inspections are the foundation of good maintenance. At least twice a year, take a close look at your valves. Check for any signs of wear, corrosion, or leakage around the stem, body, and seals. These early indicators can save you from bigger headaches down the line. Don't forget to test the valve's operation—open and close it a few times to ensure it moves freely without sticking or excessive force. If you notice any unusual resistance or noise, it's time to dig deeper. A simple visual and functional check can catch small issues before they escalate into costly repairs or downtime, keeping your system reliable and your operations uninterrupted.

Proper lubrication is another key aspect often overlooked but crucial for extending valve life. Valves have moving parts that need to stay well-lubricated to reduce friction and prevent seizing. Use the right type of lubricant recommended by the manufacturer, as using the wrong one can do more harm than good. Apply it to the stem, threads, and other moving components during scheduled maintenance. But be careful not to over-lubricate, as excess grease can attract dirt and debris, leading to clogging or contamination. In corrosive environments, consider using corrosion-resistant lubricants. This small step can significantly enhance performance and prevent premature wear, ensuring your valves continue to function smoothly even under harsh conditions.

Beyond routine checks and lubrication, proactive measures can make a huge difference. For instance, keep valves clean by removing any buildup of dirt, scale, or debris that might interfere with operation. In systems with harsh fluids or high temperatures, consider installing protective covers or using specialized materials to shield valves from damage. Also, document all maintenance activities in a log—track inspections, repairs, and replacements. This record helps you spot patterns or recurring issues, allowing for better planning and predictive maintenance. Remember, a well-maintained valve not only lasts longer but also improves overall system efficiency and safety, making these tips a smart investment in your infrastructure's longevity.

FAQ

UL FM gate valves are specifically designed for fire protection, meeting strict safety standards. They control water flow reliably in emergencies, ensuring systems activate promptly to suppress fires.

Unlike standard valves, UL FM gate valves undergo rigorous testing for fire resistance and leak prevention. They offer superior durability, handling high pressures and temperatures without failing.

Buyers should prioritize certifications like UL and FM listings, material quality such as brass or stainless steel, and ease of maintenance. Valves with clear markings and corrosion resistance ensure long-term reliability.

Yes, they are designed for compatibility with standard piping and systems. However, buyers should check valve sizes, pressure ratings, and installation guidelines to avoid mismatches with older components.

Challenges include ensuring proper alignment and avoiding debris in pipelines. Best practices involve using trained installers, conducting pressure tests, and following manufacturer instructions to maintain optimal performance.

Pricing varies by material and certification level, with bulk orders often offering discounts. Availability can be influenced by supply chain factors, so sourcing from reliable suppliers and planning ahead helps manage costs and timelines.

Conclusion

In the world of fire protection, UL FM gate valves stand as critical components that ensure safety and reliability in high-stakes environments. These valves, certified by UL (Underwriters Laboratories) and FM (Factory Mutual), are specifically designed to control water flow in fire suppression systems, making them indispensable for wholesale buyers seeking robust solutions. The importance of UL FM certification cannot be overstated—it guarantees that these valves meet rigorous standards for performance and durability under fire conditions. By integrating key features like corrosion-resistant materials, precise sealing mechanisms, and easy operation, these valves enhance overall fire safety, reducing risks and ensuring compliance with industry regulations. Their relevance extends beyond mere functionality, as they contribute to the structural integrity and effectiveness of fire protection systems in various settings.

For wholesale buyers, sourcing UL FM gate valves involves strategic considerations that balance cost-effectiveness with long-term value. Practical applications span across industries such as commercial buildings, industrial facilities, and residential complexes, where reliable fire protection is non-negotiable. To optimize procurement, buyers should focus on bulk purchasing from certified suppliers, leveraging economies of scale without compromising on quality. Additionally, regular maintenance—including inspections, lubrication, and timely replacements—is essential to sustain valve performance and prevent failures. By adopting these strategies, wholesale buyers can unlock efficient flow control, ensuring that their fire protection systems remain dependable and ready to respond in emergencies, ultimately safeguarding lives and property.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com